What is a premix?

refers to a uniformly stirred mixture of one or more additives and diluents, also known as additive premix. The purpose is to facilitate the uniform dispersion of trace raw materials in a large number of raw materials and prepare for the next step.

Scientific premix formulation is the key to premix production. To produce high-quality premixes, not only scientific formulas are needed, but also high-quality raw materials, sophisticated equipment and technology, and a complete set of management measures. Premix is not a simple commodity, but a technology with extremely high technical content. It is a comprehensive manifestation of raw material quality inspection, nutritional formula design, and livestock and poultry breeding management.

Technical points of premix production line

1. Prevent and reduce the loss of active ingredients: In order to ensure the stability and effectiveness of the premix, raw materials with good stability must be selected. In terms of vitamins, stabilized raw materials should be selected; when the storage time exceeds 3 months , Good quality antioxidants, anti-caking agents and anti-mold agents should be added.

2. Stability of trace components: under normal storage and use conditions, the physical and chemical properties of trace elements, vitamins and other components in the premix are stable, but when the moisture content is high, the stability is poor and the loss rate is large , The water content of the premix should be strictly controlled, preferably not more than 5%.

3. Measurement and mixing: For the measurement of micro-components, electronic scales should be used, and scales can be used for large amounts of raw materials. There are many kinds of mixers, and Honggong's loss-in-weight feeding scale can be used for accurate metering and batching.

4. Packaging and storage: Most pre-mixed packaging bags use three-in-one paper bags, which have the advantages of waterproof, light-proof, no leakage and not easy to damage. Generally 20-25 kg/bag. Since the premix contains a variety of active micro-components, the chance of their interaction will increase, so care should be taken to prevent moisture during storage.

What equipment does the premix system production line include?

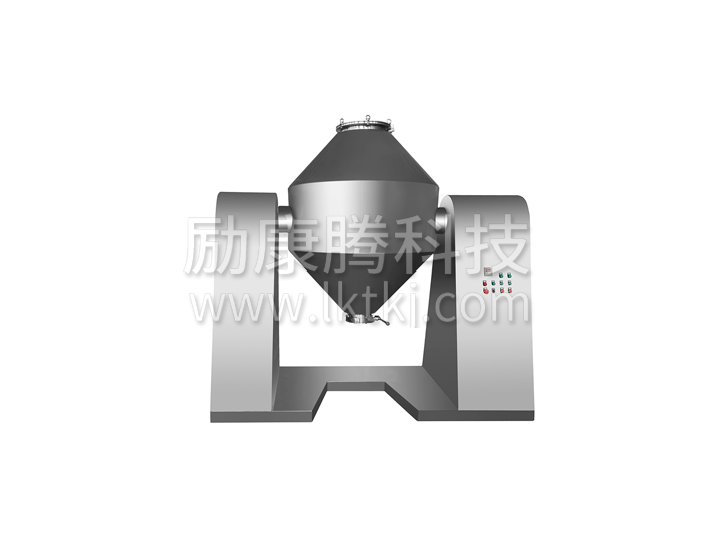

The premix system production line mainly includes bucket lifting system, small material batching system, mixing and mixing system, automatic packing system, dust removal system and PLC control system, etc. Guangdong Honggong can design a reasonable premix production line program according to actual process requirements .